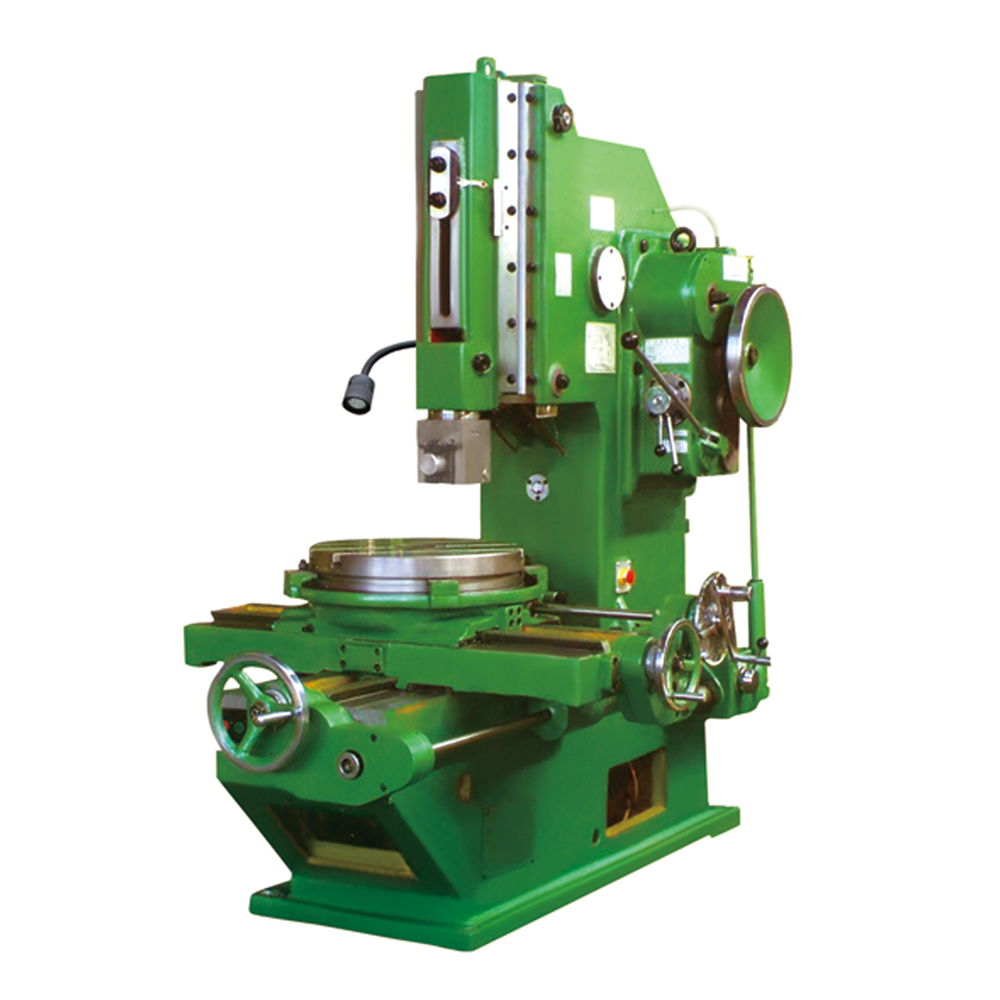

Mochini oa ho Slotting oa B5032 o Otlolohileng

Litlhaloso

| TS'ELISO | B5020D | B5032D | B5040 | B5050A |

| Bolelele ba slotting bo phahameng | 200mm | 320 limilimithara | 400mm | 500 limilimithara |

| Boholo ba litekanyo tsa workpiece (LxH) | 485x200mm | 600x320mm | 700x320mm | - |

| Boima bo boholo ba workpiece | 400kg | 500kg | 500kg | 2000kg |

| Tafole bophara | 500 limilimithara | 630 limilimithara | 710 limilimithara | 1000mm |

| Leeto le phahameng la longitudinal la tafole | 500 limilimithara | 630 limilimithara | 560/700 limilimithara | 1000mm |

| Maemo a phahameng a ho tsamaea tafoleng | 500 limilimithara | 560 limilimithara | 480/560 limilimithara | 660 limilimithara |

| Mefuta e fapaneng ea lisebelisoa tsa matla a tafole (mm) | 0.052-0.738 | 0.052-0.738 | 0.052-0.783 | 3,6,9,12,18,36 |

| Matla a motlakase a ka sehloohong | 3kw | 4kw | 5.5kw | 7.5kw |

| Kakaretso ea boholo (LxWxH) | 1836x1305x1995 | 2180x1496x2245 | 2450x1525x2535 | 3480x2085x3307 |

Melao ea Tšireletso

1. Wrench e sebelisitsoeng e tlameha ho lumellana le nate, 'me matla a lokela ho ba a loketseng ho thibela ho thella le ho tsoa kotsi.

2. Ha u koala workpiece, sefofane se setle sa litšupiso se lokela ho khethoa, 'me poleiti ea khatello le pad iron e lokela ho ba e tsitsitseng le e ka tšeptjoang. Matla a clamping a lokela ho ba a loketseng ho netefatsa hore workpiece ha e lokolohe nakong ea ho itšeha.

3. Sebaka sa mosebetsi se nang le motsamao oa linear (longitudinal, transverse) le potoloho ea selikalikoe ha e lumelloe ho etsa tse tharo kaofela ka nako e le 'ngoe.

4. Ho thibetsoe ho fetola lebelo la slider nakong ea ts'ebetso. Ka mor'a ho lokisa setorouku le boemo ba ho kenya slide, e tlameha ho koaloa ka thata.

5. Nakong ea mosebetsi, u se ke ua atolosa hlooho ea hau ka har'a sekhahla sa slide ho shebella boemo ba machining. Stroke e ke ke ea feta lintlha tsa sesebelisoa sa mochini.

6. Ha u fetola likere, u fetola lisebelisoa, kapa li-screw tse tiisang, koloi e tlameha ho emisoa.

7. Ka mor'a hore mosebetsi o phethoe, letsoho le leng le le leng le lokela ho behoa sebakeng se se nang letho, 'me benche ea mosebetsi, mochine oa mochine, le sebaka se potolohileng mochine oa mochine se lokela ho hloekisoa le ho hloekisoa.

8. Ha u sebelisa crane, thepa ea ho phahamisa e tlameha ho ba e tiileng le e ka tšeptjoang, 'me ha e lumelloe ho sebetsa kapa ho feta tlas'a ntho e phahamisitsoeng. Tšebelisano e haufi le opareitara ea crane ea hlokahala.

9. Pele o khanna, hlahloba le ho tlotsa lisebelisoa tsohle, apara lisebelisoa tsa tšireletso, 'me u tlame li-cuffs.

10. U se ke ua bululela litšepe ka molomo kapa ua li hloekisa ka matsoho.